Raw material procurement

Crafting Excellence in Every Cookware We Make

At Changyuan, we are well aware of the importance of manufacturing technology to product quality, so we strive for excellence in every production link. We combine modern production equipment with years of industry experience to create high-quality non-stick cookware, ensuring that each product meets international quality standards while meeting the personalized needs of customers.

-

1.

-

2.

Material screening and testing

-

3.

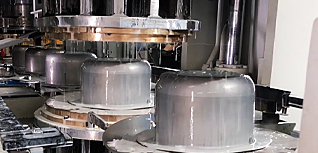

Punching and hemming

-

4.

Washing and drying

-

5.

Sandblasting and surface treatment

-

6.

Non-stick coating spray

-

7.

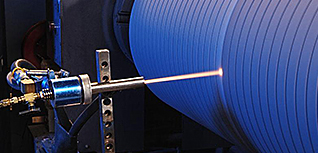

Laser engraving and personalization

-

8.

Handle installation and riveting

-

9.

Inspection and packaging

-

Diamond Coating

It is characterized by high hardness and remains wear and scratch-resistant over a long period of time. The coating is doubly reinforced with real diamonds: 33 carats per kilogram of dry coating.

1. Top coat, extra protection providing excellent release properties

2. Special layer reinforced with real diamond particles, guarantees a better scratch and abrasion resistance

3. Mid-coat, ultra reinforced with hard mineral particles

4. Primer coat, for maximum adhesion -

Ceramic Coating

Ceramic coatings can improve the wear resistance of materials, reduce wear and tear and usually have good chemical stability to protect the substrate from corrosion.

1. Stone-effect finishing, for improved abrasion resistance and non-stick properties

2. Top coat, provides excellent release

3. Mid-coat, ultra reinforced with hard mineral particles for improved scratch and abrasion resistance

4. Primer coat, ultra reinforced with hard mineral particles for maximum adhesion

-

Granite Coating

Provides durability and non-stick properties. This coating is usually made of synthetic materials designed to simulate the hardness and high temperature resistance of granite, non-stick pans.

1. Stone-effect finishing, for improved abrasion resistance and non-stick properties

2. Top coat, provides excellent release

3. Mid-coat, reinforced with mineral particles for improved scratch and abrasion resistance

4. Primer coat, ultra reinforced with hard mineral particles for maximum adhesion -

Water-Based Coating

Water-based coating is an environmentally friendly non-stick coating that contains no or very little volatile organic compounds (vocs) and has less impact on the environment and human health.

1. Transparent layer, provides excellent releases

2. Silk-screen printing, reinforces the coating

3. Pb-layer, special layer made of extra resistant material

4. Top coat, provides extra protection

5. Mid coat, provides enhanced scratch and abrasion resistance

6. Primer coat, for the maximum adhesion

Español

Español عربى

عربى